In this second week I’ve been working on making some prototypes. I ordered some bouncing balls. Made them hollow on the inside and see if I could attach them to each other again. I also worked on teaching myself the very basics of Fusion 360 this is a great channel and learn how to 3d print. I made

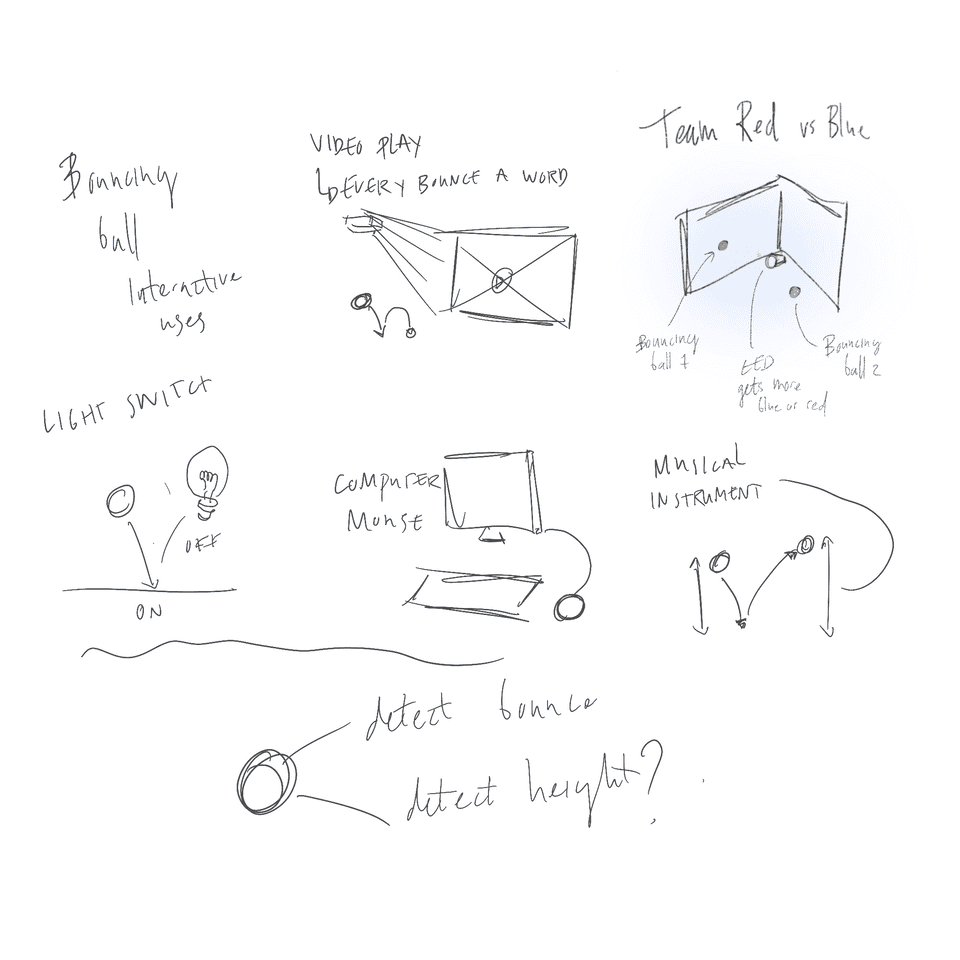

Types of interactions

Here’s some type of interaction I’ve been thinking about. Initially I was only thinking of passing one type of data to the computer (the bounce), but now I’ve been thinking it might also give more interesting effects if I add the height of the ball in comparison with the floor. Still have to figure out how to do this though, and how you would callibrate it.

Working on the fabrication

I first bought some balls from Amazon. They have a diameter of 60mm, which is pretty big. It would be better if they were a little less heavy. I initially cut them open with a utility knife. I initially tried using a Dremel to make them hollow, but this wasn’t working that great. I also noticed that the plastic started to burn. So instead I used a drilling machine to make them hollow. This seemed like the best approach so far.

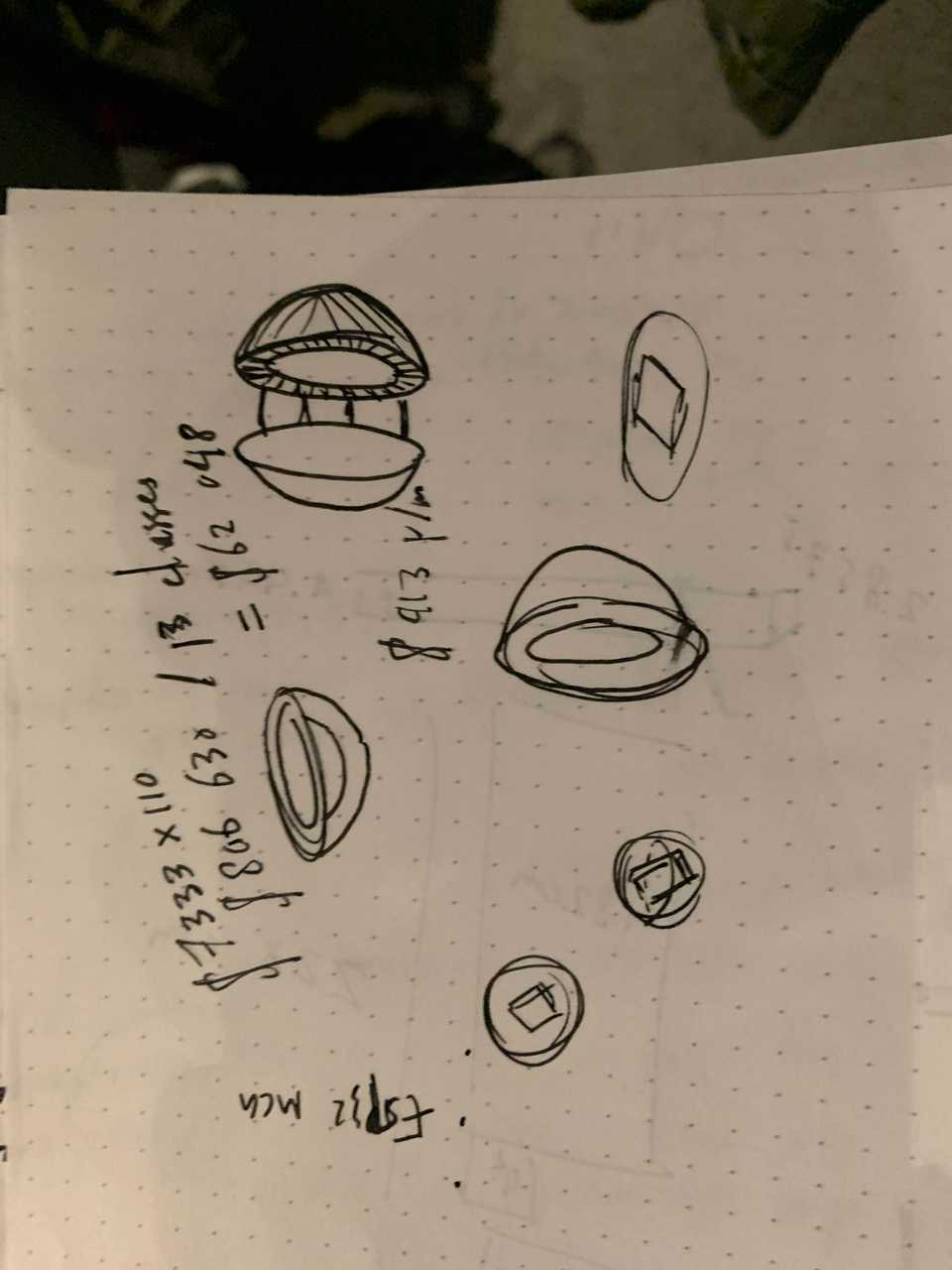

However the most elegant solution would probably be to make a 3d model and to figure out how to make it bouncy afterwards. Here’s the model.

The 3d printing was a real pain. I had a lot of troubles to make it stick to the plate. The best settings that worked for me was to add support and adhesion (build plate adhesion type is brim). However what worked best was to cut the printing speed in half to 40mm/s.